Axces has designed, engineered and produced the five complete air intake and exhaust systems for 20MW Emergency Power of a Nuclear Powerplant.

That power is used to cool the nuclear reactor in times of grid power failures and emergency situations and were designed according to IAEA (International Atomic Energy Agency) safety standards.

The scope of the delivery included:

- Ultra low noise Air Intake System

- High attenuation Exhaust System with integrated Exhaust Silencer

- Freestanding, earthquake proof and CE Marked Chimney

All of the components of the system have been delivered in compliance with ultra srict quality and safety regulations.

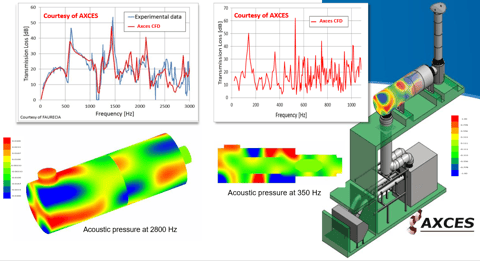

The complete exhaust system was calculated using extensive CFD Analyses in order to fulfil the powerplant requirements with regards to

Back Pressure, Attenuation of the exhaust silencer and total noise levels at the exhaust outlet.

In order to assure the lifetime and safety the following verification and validations were done:

- Dynamic Load Analyses on the structure due to vibrations and gas pulsations (High Cycle Fatigue)

- Proof Load analyses

- Thermal load analyses (Low Cycle Fatique)

- Lifting lug strength analyses

- Modal Analyses

- Harmonic Analyses in order to verify Modal Frequency Requirements

- Seismic analyses of the chimney

In order to verify and guarantee the required noise levels of the plant, Axces carried out analyses of the Transmission and Insertion loss over the exhaust silencer as well as the complete exhaust system. Using 3D models and complex calculations, the strict noise level at the outlet of the chimney were in compliance.

In order to verify and guarantee the required noise levels of the plant, Axces carried out analyses of the Transmission and Insertion loss over the exhaust silencer as well as the complete exhaust system. Using 3D models and complex calculations, the strict noise level at the outlet of the chimney were in compliance.

Besides the exhaust noise of the system, the following technical analyses were done:

- Tailpipe Noise

- Flow Induced Noise

- Body Radiated Noise

- Pressure Loss over the complete system

- Thermal Expansion

- Heat radiation of the system

- Reduction in Vibration transferred to the structure

Questions?

Please feel free to contact us for more information.